A pdf of the complete submission can be found here.

Submission

Part 6, Substance specific requirements, Combustible dust, Sections 6.133-6.166

Part 4, General conditions, Sections 4.17 and 4.42

Part 5, Chemical agents and biological agents, Section 5.71

Part 31, Firefighting, Section 31.5

The BC Federation of Labour (“BCFED” “Federation”) appreciates the opportunity to provide our recommendations with respect to the proposed amendments for Part 6, Combustible Dust and subsequent changes to Part 4, General Conditions, Part 5, Chemical Agents and Biological Agents and Part 31, Firefighting.

The Federation represents more than 500,000 members of our affiliated unions, from more than 1,100 locals working in every aspect of the BC economy.

The Federation is recognized by the Workers’ Compensation Board (“WCB,” “Board”) and the government as a major stakeholder in advocating for the health and safety of all workers in BC and full compensation for injured workers.

And we are especially pleased to participate when our recommendations made in the public consultations are reflected in the proposed amendments.

For example, we are pleased to see the inclusion of the joint health and safety committee or the worker health and safety representative in Section 6.135 (2). The employer is required to consult on the preparation and updating of the combustion risk assessment, a combustible dust management program and the provision of instruction and training.

Section 6.135(2) affirms the legislated role of the health and safety committee, the worker representative and workers in workplaces where there is no committee to participate in workplace health and safety as determined by the Workers Compensation Act (WCA), Part 2 Division 4.

We urge the Board of Directors to seriously consider our recommendations so we meet our goal to ensure that BC health and safety regulations set standards that will prevent workers from injury and death.

This submission was prepared in consultation with our affiliates. The BCFED is grateful to United Steelworkers (USW) for their expertise and insight into combustible dust and their assistance with this regulatory review.

We will address those sections of the regulation we believe require further amendments.

Introduction

The proposed combustible dust regulation resulted from the tragic dust explosions at the Babine Mill in Burns Lake and Lakeland Mill in Prince George in January and April of 2012. The Babine Mill explosion killed Robert Luggi Jr. and Carl Charlie and injured 19 workers. The Lakeland Mill explosion killed Alan Little and Glenn Roche and injured 24. Many of those workers who were injured suffered life-altering physical and psychological injuries. These tragic events continue to impact families, co-workers and whole communities.

BCFED President Sussanne Skidmore lived in Prince George at the time of the Lakeland Mill explosion. She recalls standing on her patio, hearing sounds of the explosion, seeing the smoke coming off the buildings and wondering if she knew any of the workers on shift that day. It turned out she did know many of the workers on that shift because Prince George is a small, close-knit community. Sussanne, who at the time was the first Vice Chair of the North Central Labour Council, worked with the United Steelworkers to support the injured workers and the surviving families.

Crown Counsel reviewed both cases and determined that no criminal charges would be laid, citing the WCB substandard investigation process as the main reason. The employers were given the largest WCB fines at the time. Babine Mill was fined over a million dollars and the Lakeland Mill $724,000.

The government also commissioned two reports in 2014 — the Dyble Report and the Macatee Report. Together, these reports and the 2015 BC Coroners Service verdicts included numerous recommendations directed at government and other agencies on how to make improvements to workplace safety, inspections, education, enforcement and investigations.

Coroner’s inquests were held in 2015 into both explosions, but these inquests, as a strictly fact-finding process, left the families and the victims with more questions than answers.

The families were profoundly disappointed and in 2016 called for a public inquiry into the two incidents – the United Steelworkers and the BCFED supported their demand.

In 2019, the government contracted lawyer Lisa Helps to assess both government and WCB’s progress in implementing recommendations stemming from past reports. In the report Crossing the Rubicon, Helps found all recommendations from these reports have been implemented and the changes have largely been effective and positive. She was also tasked with making recommendations for further actions to strengthen investigations to ensure those responsible for workplace incidents are held accountable.

In 2014, the WCB introduced three new policies under the WCA relating to wood dust mitigation and control: P 2-21-3 Employer Duties; P 2-22-2 Worker Duties and P-23-3 Supervisor Duties.

These policies were introduced because the Occupational Health & Safety Regulation (OHSR) has no regulation specific to combustible dust.

The intent of the proposed amendments is to provide more robust and structured regulatory requirements for workplace combustible dust.

The BCFED appreciates the work of the WCB on this important project.

Once the regulation is implemented, BC will lead the world in having the first combustible dust regulation.

Section 6.133 (1), Definitions

Recommendation

The BCFED recommends removing both “combustible dust management program” and “combustible dust provisions” from definitions as these are not definitions but directions on where to find them in the regulation.

Combustion risk assessment

Recommendation

The BCFED recommends amending this definition and using the term “combustible dust risk assessment” to be consistent with the definition of combustible dust.

Combustible dust ignition

The BCFED believes there is a need to provide a more robust definition or an explanation of combustible dust ignition. Many of the standards and guidance documents for combustible dust refer to the criteria that are required for ignition, for example, from the National Fire Prevention Association (NFPA). Included in this example is a reference to minimum explosible concentration as defined in Section 6.133 and in (3) a list of ignition sources. Section (2) refers to the minimum explosible concentration (MEC) which is included in the proposed definitions and makes an important link to combustible dust ignition cause.

We believe ignition sources are not properly defined in the proposed definitions, only in relation to when there is a significant ignition source sufficient to ignite dust when it is suspended in the air or when the dust is not suspended in the air.

NFPA 499, Section 4.1.1 Criteria for Combustible Dust Ignition.

The pertinent criteria for ignition of any combustible dust cloud or layer include the following:

(1) Air

(2) The material form either dispersed in air (oxidant) at or exceeding the minimum explosible concentration (MEC) for an explosion or in a layer at or exceeding the layer ignition temperature

(3) Ignition source(s) such as an electrostatic discharge, an electric current arc or spark, a glowing ember, a hot surface, welding slag, frictional heat, or a flame.[1]

In the OSHR, Part 5, Section 5.27 (2) Ignition sources specific to combustible liquids are listed:

(2) For the purposes of subsection (1) sources of ignition include open flame, spark-producing mechanical equipment, welding and cutting processes, smoking, static discharge and any electrical equipment or installation that is not permitted under the B.C. Electrical Code for use in hazardous locations.

Recommendation

The BCFED recommends a further amendment to the combustible dust ignition definition to include the NFPA criteria for combustible dust ignition, including a list of ignition sources as per OSHR Part, Section 5.27 (2).[2]

Alternately an amendment referencing Section 5.27(2) could be added to the definition of competent ignition sources.

This is a new regulation, one which many workers and employers will be required to implement for the first time, and we believe this amendment provides a clearer explanation and definition of the criteria involved in a combustion ignition and the sources of ignition.

Vacuum cleaning system. Section 6.133(2)

This definition includes the term “for certainty in reference to machinery or equipment in the following provisions is to be read to include an enclosure use for bulk storage of combustible dust.”

Recommendation

The BCFED recommends removing “for certainty” from Section 6.133(2), Vacuum cleaning system as the term is not commonly used in the OHSR and it serves no purpose in this context and is therefore unnecessary.

Section 6.137, Identification of combustible dust-ignitability; and Section 6.138, Identification of combustible dust-deflagrability

These sections determine for the purposes of Section 6.136 (2) or (3)(a), the employer must consult with a qualified person and provide acceptable methods to establish by analysis whether a dust is ignitable and deflagrable or not.

Section 6.137, Subsection (a)(i) refers to a specific standard to test samples to determine ignitability. Similarly, Section 6.138, Subsections (a)(i)(ii) refer to specific standards for testing for deflagrability.

In both sections the WCB allows for “a similar screening test published by a national or international body or standards association.”

There is no explanation for this requirement in the explanatory notes, and we are left wondering as to the reasons why the WCB is allowing other standards that are unnamed to determine ignitability.

There is model language in OHSR Part 6, Respirable Crystalline Silica (RCS) and Rock Dust, Section 6.112.3 Air monitoring for RCS dust,

(2) Acceptable sampling and analytical methods for the purpose of subsection (1) are as follows:

(a) a method detailed in a standard occupational hygiene reference published by

(i) the National Institute for Occupational Safety and Health, or

(ii) the Occupational Safety and Health Administration;

(b) another method acceptable to the Board.[3]

Recommendation

The BCFED recommends Sections 6.137(a)(ii) and 6.138 (a)(iii) be removed and a new section modelled on Section 6.112.3, Air Monitoring for RCS be added to each section.

Examples of testing methods for combustible dust would be the NFPA,[4] the European Parliament Directive 1999/92/EC requirements for combustible dust,[5] and the ISO/ 80079 Part 20-2, Combustible testing methods.[6]

Qualified person

The explanatory notes address the role of a qualified person (QP) first appearing in Sections 6.137 and 6.138 and found throughout the proposed amendments.

The definition of “qualified” found in the OHSR Part 1, Definitions Section 1.1 will apply to all Part 6 sections requiring the employer to consult with a qualified person.

"Qualified" means being knowledgeable of the work, the hazards involved and the means to control the hazards, by reason of education, training, experience or a combination thereof.[7]

The employer is required to consult with a qualified person in the following sections of the regulation:

- Sections 6.137 and 6.138 in the identification of combustible dust ignitability and deflagrability;

- Section 6.139, Risk assessment;

- Sections 6.140 and 141, Combustible dust management program and program review;

- Section 6.149(1)(b) and (3), Bulk storage, emergency response plan and deflagrability;

- Section 6.151, Removal of combustible dust, (2) Where dust could accumulate on surfaces;

- Section 1.52, Metal dusts;

- Section 6.153, Other requirements for metal dust;

- Section 1.64, Risk controls;

- Section 6.157(3), Dust collection systems;

- Section 6.165, Fire control; and

- Section 6.166, Deflagration control.

In the Explanatory Notes, the WCB acknowledges the QP role may be fulfilled by different people for the different requirements of the regulation. For example, Section 6.125, Fire control, the QP should be a fire protection engineer.

The BCFED is very concerned no requirements are set out in the regulation to identify how these QPs are identified. No requirements for determining qualifications, certification, training nor job experience. According to the Explanatory Notes, the WCB will develop guidelines to provide direction on the varying roles and responsibilities of a QP in the different sections of the regulation.

We believe this information must be placed in the regulation to give clear directions to employers when they are considering who the QP will be. We are worried that upon implementation of this regulation, there will be people “hanging out their shingle” who are not qualified to do this work.

We strongly believe given the elevated risk of combustible dust incidents, the WCB must establish acceptable requirements for QPs in the regulation. It is within the WCB’s mandate.

And there is an example to follow in the OSHR, Part 9, Section 9.11, Confined spaces,

9.11 Qualifications

(1) The hazard assessment and written confined space entry procedures must be prepared

(a) by a qualified person who has adequate training and experience in the recognition, evaluation and control of confined space hazards, and

(b) in consultation with the person assigned overall responsibility for administration of the confined space entry program and with the joint committee or the worker health and safety representative, as applicable.

(2) For the purposes of subsection (1)(a) qualifications which are acceptable as evidence of adequate training and experience include

(a) certified industrial hygienist (CIH), registered occupational hygienist (ROH), certified safety professional (CSP), Canadian registered safety professional (CRSP) or professional engineer (P. Eng.), provided that the holders of these qualifications have experience in the recognition, evaluation and control of confined space hazards, or

(b) Repealed. [B.C. Reg. 243/2006, effective January 1, 2007.]

(c) other combination of education, training and experience acceptable to the Board.[8]

Recommendation

The BCFED recommends a further amendment to Part 6, Combustible dust, adding a new section on qualified persons modeling the language of Part 9, Confined space, Section 9.11, Qualifications.

The BCFED believes this will provide clarity to employers, workers and prevention officers and ensure there are specific and mandatory requirements for determining qualifications.

Further information and guidance could be included in the guidelines.

Section 6.139, Combustion dust risk assessment

As previously stated in this submission, amend this section to “Combustible Dust Risk Assessment.”

The section sets out the requirements for combustion risk assessment of any type of dust present in the workplace.

Subsection (1)(a)

“(a) Prepare the assessment as soon as practicable, and”

The BCFED strongly disagrees with the word “practicable” as applied to when an employer must perform a risk assessment.

“Practicable” as defined in OHSR, Part I, Definitions: “means that which is reasonably capable of being done.”[9]

In a quick perusal of other Sections of Part 6, Substance specific requirements, we could not find reference to the word “practicable” in the requirements for a risk assessment.

In Part 6, Asbestos section, 6.6, Risk assessment:

(1) The employer must ensure that a risk assessment is conducted by a qualified person on asbestos-containing material identified in the inventory referred to in section 6.4(1)(c) or (3), as applicable, with due regard for the condition of the material, its friability, accessibility and likelihood of damage, and the potential for fibre release and exposure of workers.

(2) The employer must ensure that a risk assessment has been conducted by a qualified person before any demolition, alteration, or repair of machinery, equipment, or structures where asbestos-containing material may be disturbed.

Nor in Part 6, Lead section 6.59 (2), Risk assessment:

(2) An employer must not permit workers to engage in a work activity or lead process that may expose workers to lead dust, fumes or mist unless a risk assessment has first been completed by a qualified person.

Similarly, practicable is not in Part 6 Respirable Crystalline Silica:

Section 6.112 Risk assessment

(2) An employer must not permit workers to engage in a work activity or a silica process that may expose workers to RCS dust unless a risk assessment has first been completed by a qualified person.

In these sections a risk assessment “must” be completed not when it suits the employer, and it is inappropriate to use the word “practicable” in these risk assessments. Risk assessments are an integral part of an occupational health and safety management program.

According to the Canadian Centre for Occupational Health and Safety, risk assessment is a term used to describe the overall process or method where you:

- Identify hazards and risk factors that have the potential to cause harm (hazard identification).

- Analyze and evaluate the risk associated with that hazard (risk analysis, and risk evaluation).

- Determine appropriate ways to eliminate the hazard, or control the risk when the hazard cannot be eliminated (risk control).[10]

The new combustible dust regulation is intended to prevent the catastrophic events that have caused worker deaths and injuries in BC.

Recommendation

The BCFED therefore strongly recommends Subsection 1(a) be removed and Section (1) amended to say an employer must prepare a combustion dust risk assessment.

Section 6.140, Combustible dust management program

Section 6.140 sets the requirements for preparing a combustible dust management program, how it must be prepared and who must administer the program.

Subsection (1)(a) and (b)

Recommendation

The BCFED recommends removing the word “practicable” in both subsections and rewording Section (1) to state the employer “must” prepare and implement a program.

The BCFED also recommends amending Subsection (b) to “update the program after a review under Section 6.141, if changes are necessary to minimize combustion risks.”

Our comments in Section 6.139 regarding our concerns with the use of “practicable” apply to these subsections.

Subsection (2)(e)

“Include procedures for responding to an unintended combustion of dust.”

We are curious why the word “unintended” is used in this subsection to refer to a combustion event. The Oxford Dictionary defines “unintended” as “an unintended effect, result, or meaning is one that you did not plan or intend to happen.”[11]

We cannot imagine a combustible dust event would be planned.

Recommendation

The BCFED recommends the WCB further amend Section 6.140 (2)(e) with a more appropriate word to describe a combustion event in this context.

Subsection (4)

This subsection sets out the requirement for the employer to assign responsibility for the administration of the combustible dust management program to a “single individual” who,

- Is the employer or an employee of the employer, and

- Is knowledgeable about

- the controls described in the program, and

- the safe operation of the relevant machinery and equipment.

The WCB explains in their Explanatory Notes that “a single individual is required as a point-person to coordinate and oversee the overall activities of a program to ensure the program is robust and functioning properly and as intended.”

The BCFED opines this must be the duty of the employer or the supervisor according to WCA Part 2, Division 4, Sections 21 and 23, General duties of employers and supervisors.[12]

A similar requirement can be found in Part 9, Confined space, Section 9.6 of the OHSR, “The employer must assign overall responsibility for administration of the confined space entry program to a person or persons adequately trained to do so.”[13]

And from Guideline G9.6

The administration of the program required by section 9.5 may be undertaken by the employer's own staff, or it may be assigned to another person or persons. The person(s) appointed responsible for administration of the program must be given the authority and means to ensure the effective operation of the program.[14]

OHSR Section 9.6 allows the overall responsibility for the administration of the confined space entry program to be assigned to a person or persons.

Given the organizational structure of a workplace: work shifts, vacation, sick days, we believe that giving this responsibility to one person will inevitably mean there will be gaps when the person is not available. For example, the assigned person may not be able to ensure the program is robust and functioning properly if the assigned person not available during an incident.

And the assigned person or persons must be knowledgeable and trained for this role, and as per Guideline 9.6, must be given the authority and means to ensure the program is effective.

Recommendation

The BCFED recommends a further amendment to Section 6.140, Subsection 4 stating that responsibility for administration or the combustible dust program be assigned to a person or persons knowledgeable and trained to do so.

Section 6.142, Instruction and training

Section 6.142 sets out the requirements for instruction and training for workers who could be exposed to a combustion hazard. According to the Explanatory Notes, the degree of instruction and training may vary for different workers based on their exposure as it relates to their work location and work activities.

The BCFED strongly disagrees with the potential exclusion of workers from instruction and training based on their exposure. All workers have a right to know about the hazards at their workplace and the employer is required to provide training and education for all workers.

Combustible dust explosions level workplaces and kill and injure workers. In the two mill explosions in BC, four workers died, many workers were injured, and buildings and structures were destroyed. The only workers who were not directly impacted were those who were not at work at the time of the explosions.

We cannot overstate the importance of increasing awareness at workplaces with combustible dust.

The Dust Safety Science Expert Opinion Round-up asked international combustible dust experts to identify the number one problem facing industries handling combustible dust. There was a common concern about a lack of understanding and knowledge about combustible dust at workplaces.

For example,

It is the intent here to not restate the obvious issue of education. Understanding the regulations and standards for each combustible dust application as it applies to each industrial sector is critical to mitigating risk.

The single most important problem facing industries handling combustible dust continues to be hazard communication. Combustible dust explosions and fires continue to occur in workplaces where management and their employees were unaware of combustible dust hazards.

In Canada, the biggest problem is combustible dust hazard awareness.

One of the biggest problems with combustible dusts is most companies do not understand that their dusts are combustible or if you mention that it may be a hazard, they immediately think biological.[15]

Recommendation

The BCFED therefore recommends Section 6.142 be amended to be inclusive by ensuring all workers be provided with instruction and training.

Subsections (a)(b) (c)

These sections set out the content of the instruction and training:

- The combustion hazard.

- The factors that could increase the combustion risk posed by the combustion hazard.

- The applicable parts of the combustible dust management program.

Recommendation

We recommend Subsections (a) and (c) be amended to align with Section 6.135(2), consultation with the joint committee, worker representative or representative sample of workers.

- Combustible dust risk assessment

c) Combustible dust management program

And add new sections:

(d) Risk controls;

(e) fire control;

(f) deflagration control;

(g) procedures after a fire or deflagration; and

(h) Section 6.149, Bulk storage, Subsection (1)(b) that requires the employer to ensure workers comply with a written emergency response plan that sets out procedures and methods for responding to combustion of dust and determining if the burning is extinguished.

For further suggestions on training content, see the WCB tool-box talk guide describing the information employers should provide in education for workers: https://www.worksafebc.com/en/resources/health-safety/toolbox-meeting -guides/combustible-wood-dust-awareness-and-controls?lang=en.

Section 6.144, Availability of records

Recommendation

The BCFED recommends further amending this section by removing “if applicable” to ensure that all records are made available to the joint health and safety committee or worker representative.

Sections 6.145-6.153, Combustible dusts – Risk controls (General); Sections 6.154-6.164, Risk controls (Machinery and equipment); Sections 6.165 - 6.167, Risk controls (Fire and deflagration control)

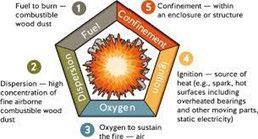

According to the Explanatory Notes, Sections 6.145 to 6.153 set out risk controls requirements intended to focus on the five Dust Explosion Pentagon Factors.

But there is no specific reference to the Dust Explosion Pentagon Factors in the regulation. The pentagon is commonly used in health and safety standards and education materials about combustible dust. The BCFED believes it must be added to the regulation as it is an important tool to increase understanding of combustible dust at workplaces.

But there is no specific reference to the Dust Explosion Pentagon Factors in the regulation. The pentagon is commonly used in health and safety standards and education materials about combustible dust. The BCFED believes it must be added to the regulation as it is an important tool to increase understanding of combustible dust at workplaces.

Recommendation

The BCFED recommends adding the Dust Explosion Pentagon Factors to Section 6.133, Definitions.

The Explanatory Notes for Sections 6.145-6.153 say the requirements for controlling the risk posed by combustible dust are performance-based, rather than prescriptive in order that they can apply to employers of all sizes and to a broad range of industries.

Notably missing is the hierarchy of controls. The hierarchy is a fundamental principle of occupational health and safety and provides steps to follow to minimize risk if it cannot be eliminated.

The WCB provides an excellent explanation of the hierarchy of controls in their guidance on controlling combustible dust risk.[16]

OSHR Part 5, Section 5.55, Type of controls, requires the employer to eliminate worker exposure to a hazardous substance or otherwise control it below harmful levels by adhering to the hierarchy of controls.

Section 5.55 Type of controls

(1) If there is a risk to a worker from exposure to a hazardous substance by any route of exposure, the employer must eliminate the exposure, or otherwise control it below harmful levels and below the applicable exposure limit established under section 5.48 by

(a) substitution,

(b) engineering control,

(c) administrative control, or

(d) personal protective equipment.

(2) When selecting a suitable substitute, the employer must ensure that the hazards of the substitute are known, and that the risk to workers is reduced by its use.

(3) The use of personal protective equipment as the primary means to control exposure is permitted only when

(a) substitution, or engineering or administrative controls are not practicable, or

(b) additional protection is required because engineering or administrative controls are insufficient to reduce exposure below the applicable exposure limits, or

(c) the exposure results from temporary or emergency conditions only.[17]

Recommendation

The BCFED recommends to further amend Section 6.145(1) to add to Combustible Dusts – Risk Control, the hierarchy of controls and require employers to implement control measures according to the hierarchy as required in Part 5, Section 5.55 Types of Controls,

(1) If there is a risk to a worker from exposure to a hazardous substance by any route of exposure, the employer must eliminate the exposure, or otherwise control it below harmful levels and below the applicable exposure limit established under Section 5.48 by

(a) substitution,

(b) engineering control,

(c) administrative control, or

(d) personal protective equipment.

More information on examples of control measures in each step can be provided in guidelines.

The BCFED believes this is an important amendment that embeds the hierarchy of controls in the regulation and will provide much-needed, clear direction and assistance to workers and employers on how to fix a hazard. The current language throughout the sections on control measures is confusing.

Section 6.165, Fire control

This section sets out the requirements for the employer to have a way to supress a fire at the workplace. And the employer must use a means that is Subsection (1)(a) “selected and if applicable, installed in consultation with a qualified person.”

The BCFED believes the dangerous nature of a combustible fire demands a requirement for a qualified person. A combustible dust expert at the pre-consultation made the comment they are the hardest fires to extinguish.

Section 6.166, Deflagration control

Subsection (a)

This section sets out the requirements for an employer to “be able to minimize the effects of a deflagration involving the dust in the workplace using a means that is selected and if applicable installed in consultation with a qualified person.”

The dangerous nature of a deflagration event and the high likelihood of worker death and injury requires the employer to consult with a qualified person.

Recommendation

The BCFED recommends Section 6.165 (1)(a) and Section 6.166(a) be amended by removing “if applicable” and require an employer to consult with a qualified person.

The BCFED recommends a further amendment to Section 6.166(a) to remove “be able to” in reference to minimizing the effects of a deflagration.

Part 4, General conditions, Section 4.17, Notification of Fire departments

This section requires the employer to notify fire departments of the nature and location of the hazardous substance materials or substances and methods to be used in their safe handling.

Combustible dust has been added to the list of hazardous substances.

The BCFED agrees with this amendment as fire departments will respond to combustible dust fires and explosions. This requirement ensures fire departments are prepared to respond appropriately.

An example of the dangers firefighters face is the June 10, 2023, aluminium dust fire in Berea, Kentucky.

Fire crews were called to the scene around 3:30 pm. Extinguishing the fire in the molten aluminum processing zone required firefighters to work in 320-degree heat. Their strategy involved removing the aluminum dust to deprive the fire of fuel. The task was made more difficult by the high temperatures outside, which reached the 80s. Off-duty firefighters from Berea voluntarily joined the effort to relieve their colleagues in the intense heat.

The fire chief described the fire as one of the most severe incidents in the Berea Industrial Park.[18]

Conclusion

The BCFED strongly urges the WCB Board of Directors to seriously consider our proposed amendments.

We generally support the new combustible dust regulation and appreciate the efforts of the WCB’s Policy, Regulation and Research Department.

We encourage the WCB to develop an effective implementation strategy ensuring that all workers and employers are properly informed and supported to effectively practice these new requirements. Outreach to workplaces who have combustible dust will be critical because some employers and workers will not know this is a high-risk hazard in their workplaces.

The implementation strategy must be designed to take into consideration the diversity of the community of workers.

We urge the WCB Board of Directors to provide the necessary resources to ensure effective implementation, ongoing inspections and enforcement.

Recommendations

Section 6.133 (1), Definitions

- The BCFED recommends removing both “combustible dust management program” and “combustible dust provisions” from definitions as these are not definitions but directions on where to find them in the regulation.

- The BCFED recommends amending this definition and using the term “combustible dust risk assessment” to be consistent with the definition of combustible dust.

- The BCFED recommends a further amendment to the combustible dust ignition definition to include the NFPA criteria for combustible dust ignition, including a list of ignition sources as per OSHR Part, Section 5.27 (2)

Alternately an amendment referencing Section 5.27(2) could be added to the definition of competent ignition sources.

Vacuum cleaning system. Section 6.133(2)

- The BCFED recommends removing “for certainty” from Section 6.133(2), Vacuum cleaning system as the term is not commonly used in the OHSR and it serves no purpose in this context and is therefore unnecessary.

Section 6.137, Identification of combustible dust-ignitability; and Section 6.138, Identification of combustible dust-deflagrability

- The BCFED recommends Sections 6.137(a)(ii) and 6.138 (a)(iii) be removed and a new section modelled on Section 6.112.3, Air Monitoring for RCS be added to each section.

- The BCFED recommends a further amendment to Part 6, Combustible dust, adding a new section on qualified persons modeling the language of Part 9, Confined space, Section 9.11, Qualifications.

Section 6.139, Combustion dust risk assessment

- The BCFED strongly recommends Subsection 1(a) be removed and Section (1) amended to say an employer must prepare a combustion dust risk assessment.

Section 6.140, Combustible dust management program; Subsection (1)(a) and (b)

- The BCFED recommends removing the word “practicable” in both subsections and rewording Section (1) to state the employer “must” prepare and implement a program.

- The BCFED also recommends amending Subsection (b) to “update the program after a review under Section 6.141, if changes are necessary to minimize combustion risks.”

Section 6.140, Subsection (2)(e)

- The BCFED recommends the WCB further amend Section 6.140 (2)(e) with a more appropriate word to describe a combustion event in this context.

Section 6.140, Subsection (4)

- The BCFED recommends a further amendment to Section 6.140, Subsection 4 stating that responsibility for administration or the combustible dust program be assigned to a person or persons knowledgeable and trained to do so.

Section 6.142, Instruction and training

- The BCFED recommends Section 6.142 be amended to be inclusive by ensuring all workers be provided with instruction and training.

Section 6.142, Instruction and training, Subsections (a)(b)(c)

- We recommend Subsections (a) and (c) be amended to align with Section 6.135(2), consultation with the joint committee, worker representative or representative sample of workers.

- Combustible dust risk assessment

c) Combustible dust management program

And add new sections:

(d) Risk controls;

(e) fire control;

(f) deflagration control;

(g) procedures after a fire or deflagration; and

(h) Section 6.149, Bulk storage, Subsection (1)(b) that requires the employer to ensure workers comply with a written emergency response plan that sets out procedures and methods for responding to combustion of dust and determining if the burning is extinguished.

Section 6.144, Availability of records

- The BCFED recommends further amending this section by removing “if applicable” to ensure that all records are made available to the joint health and safety committee or worker representative.

Sections 6.145-6.153, Combustible dusts – Risk controls (General); Sections 6.154-6.164, Risk controls (Machinery and equipment); Sections 6.165 - 6.167, Risk controls (Fire and deflagration control)

- The BCFED recommends adding the Dust Explosion Pentagon Factors to Section 6.133, Definitions.

- The BCFED recommends to further amend Section 6.145(1) to add to Combustible Dusts – Risk Control, the hierarchy of controls and require employers to implement control measures according to the hierarchy as required in Part 5, Section 5.55 Types of Controls,

(1) If there is a risk to a worker from exposure to a hazardous substance by any route of exposure, the employer must eliminate the exposure, or otherwise control it below harmful levels and below the applicable exposure limit established under Section 5.48 by

(a) substitution,

(b) engineering control,

(c) administrative control, or

(d) personal protective equipment.

Section 6.165 Fire control, Subsection (1)(a), and Section 166, Deflagration control, Subsection (a)

- The BCFED recommends Section 6.165 (1)(a) and Section 6.166(a) be amended by removing “if applicable” and require an employer to consult with a qualified person.

- The BCFED recommends a further amendment to Section 6.166(a) to remove “be able to” in reference to minimizing the effects of a deflagration.

[2]https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-05-chemical-and-biological-substances#SectionNumber:5.27

[3] https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-06-substance-specific-requirements

[4] https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=652

[7] https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-defintions

[8] https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-09-confined-spaces#SectionNumber:9.11

[9] https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-01-definitions

[10] https://www.ccohs.ca/oshanswers/hsprograms/hazard/risk_assessment.html#:~:text=The%20aim%20of%20the%20risk,a%20safer%20and%20healthier%20workplace

[11] https://www.oxfordlearnersdictionaries.com/definition/american_english/unintended#:~:text=%2F%CB%8C%CA%8Cn%C9%AAn%CB%88t%C9%9Bnd%C9%99d%2F,unintended%20consequences%20of%20your%20actions

[12]https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/workers-compensation-act/part-2-occupational-health-and-safety#SectionNumber:Part2Div4Sec21

[13] https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-09-confined-spaces#SectionNumber:9.6

[14] https://www.worksafebc.com/en/law-policy/occupational-health-safety/searchable-ohs-regulation/ohs-regulation/part-09-confined-spaces#SectionNumber:9.6